The Persian

knot

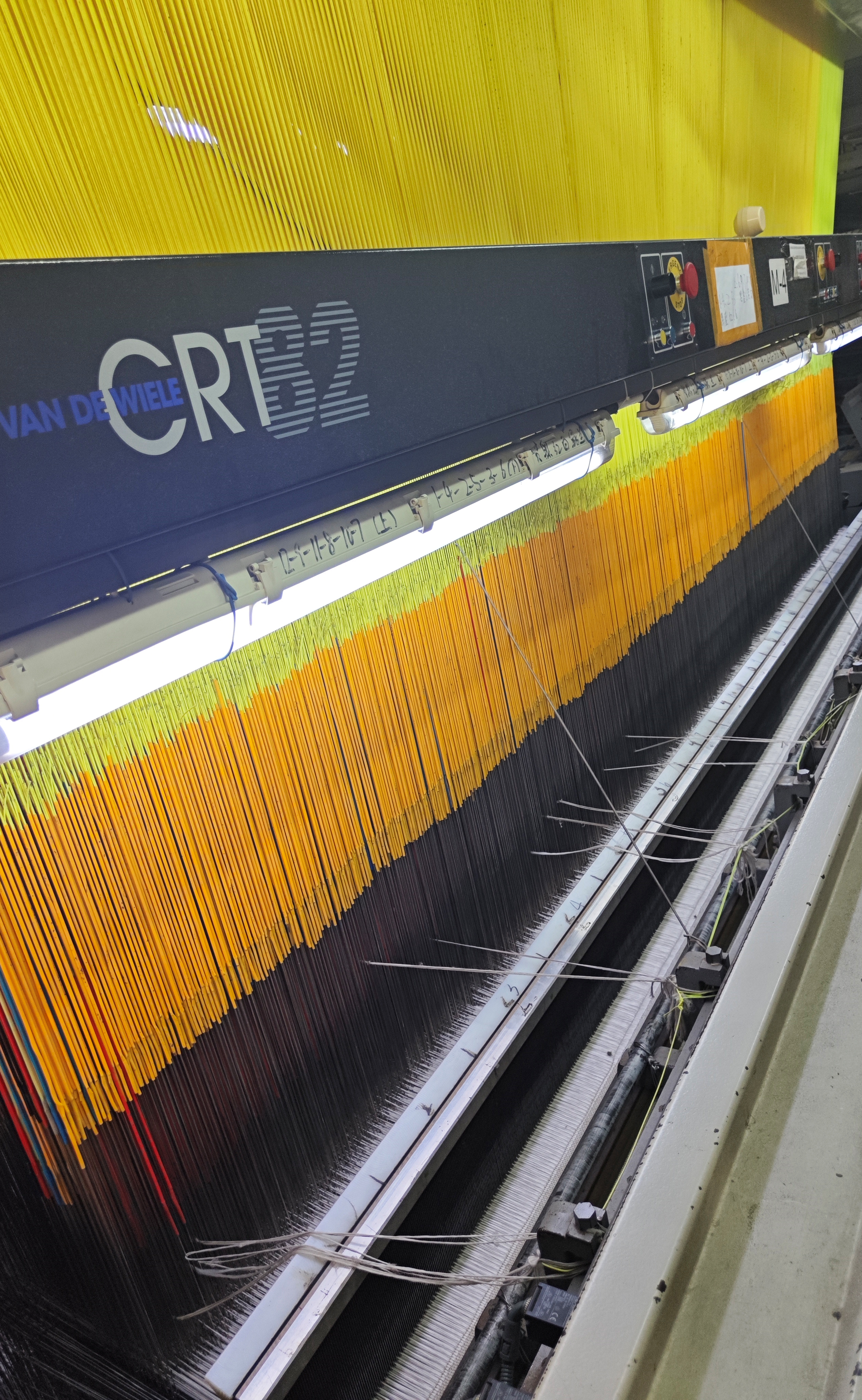

The warp threads (vertical) are stretched between two beams and the weavers, sitting side by side every 90 cm, and patiently giving birth to the rug, knot after knot, row after row, grasping the appropriate coloured strand at each knot. Weft threads (horizontal) are interwoven in the warp threads between each row of knots. This is how the rug backing is built up and consolidated. The warp and weft threads are usually made of cotton, but can be made of wool to produce nomadic rugs and in silk for fine rugs The vertical loom is also referred to as the high wrap loom.